bluthane™ TPU Film

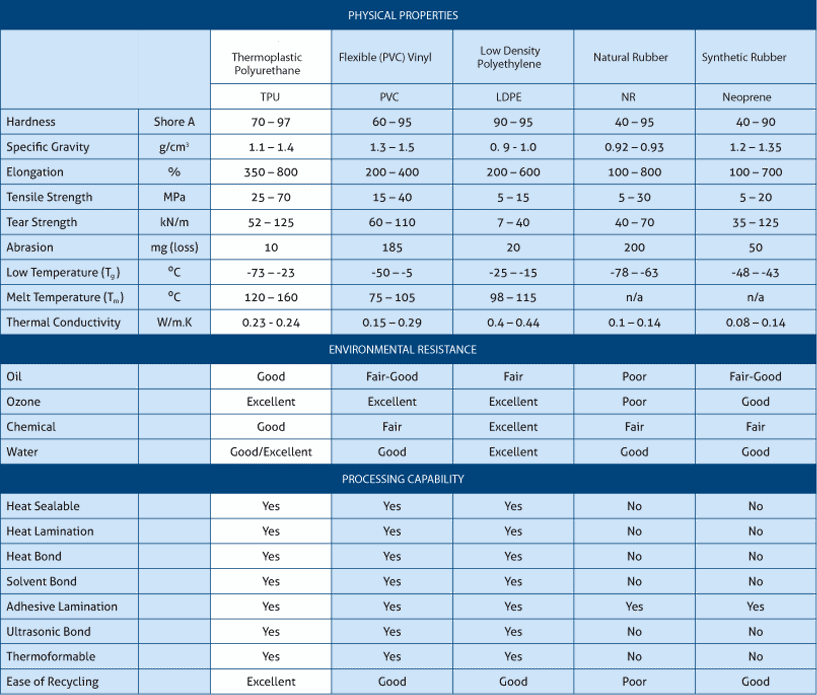

bluthane™ TPU films made from virgin granules and functional additives, are high performance products possessing excellent flexibility and toughness, many other mechanical, thermal properties and chemical properties. TPU films offer exceptional benefits such as rubber like flexibility and rigidity as plastics. Refer table below

bluthane™ films have unlimited uses in almost all situations. Majority of the applications fall in the following category. bluthane™ TPU films exhibit outstanding heat & chemical resistance, hydrolysis resistance, anti-fungus, low temperature flexibility, puncture resistance, optical clarity, wind and water proofness, weldability, paintability, and breathability.

Applications of bluthane™ TPU film

AUTOMOTIVE – Pour-in-Place Seats, Nvh Sound Deadening Components, Fuel Tank Pads, Wheel Arch Lines

APPAREL – High Fashion Garments, Breathable Fabrics, Patch , Patch Materials

INDUSTRIAL – Flexible Ventilation Hose, Conveyor Hose, Pipeline Wrap, Protective Covers, Safety Secure, Glass, Upholstery, Sewage Liners, Inflatable Balloons, Escape Slides, Conveyor Belts/ Hoses, Sound Absorption Panels

ADHESIVE – Liners, Seam Seal Tape, Garment Labels, Fabric Lamination

MEDICAL – Surgical Drapes, Inflatable Mattress, Wound Dress Taping, Gel Pads Mattress, Pillow Overlays, Transparent Gloves

FAQ’s

What is bluthane™ TPU Film?

bluthane™ TPU films are high performance blown films in the thickness range of 30 microns to 200 microns ( 0.03 mm – 0.2 mm ) manufactured from virgin thermoplastic polyurethane (TPU) granules.

What is TPU?

TPU is a high performance versatile engineering polymer, an elastomer, because of it’s flexibility combined with toughness, and bridges the gap between thermoset rubber and plastic. It is manufactured by the addition polymerization involving a long chain linear polyol, a diisocyanate and a short chain diol by batch or a continuous process using highly advancedreaction polymerization technique.

Why a TPU?

TPU is a fully reacted thermoplastic and can be processed by extrusion, injection molding and by blow molding process. Some grades are soluble in polar solvents and are used in coating and adhesives. Unlike most other thermoplastic polymer films, they can be made with minimum functional and processing additives and more importantly do not require a plasticizer like vinyls. Therefore no danger of leaching and loss of film properties, and have outstanding abrasion resistance , long-term flexibility and shelf life.